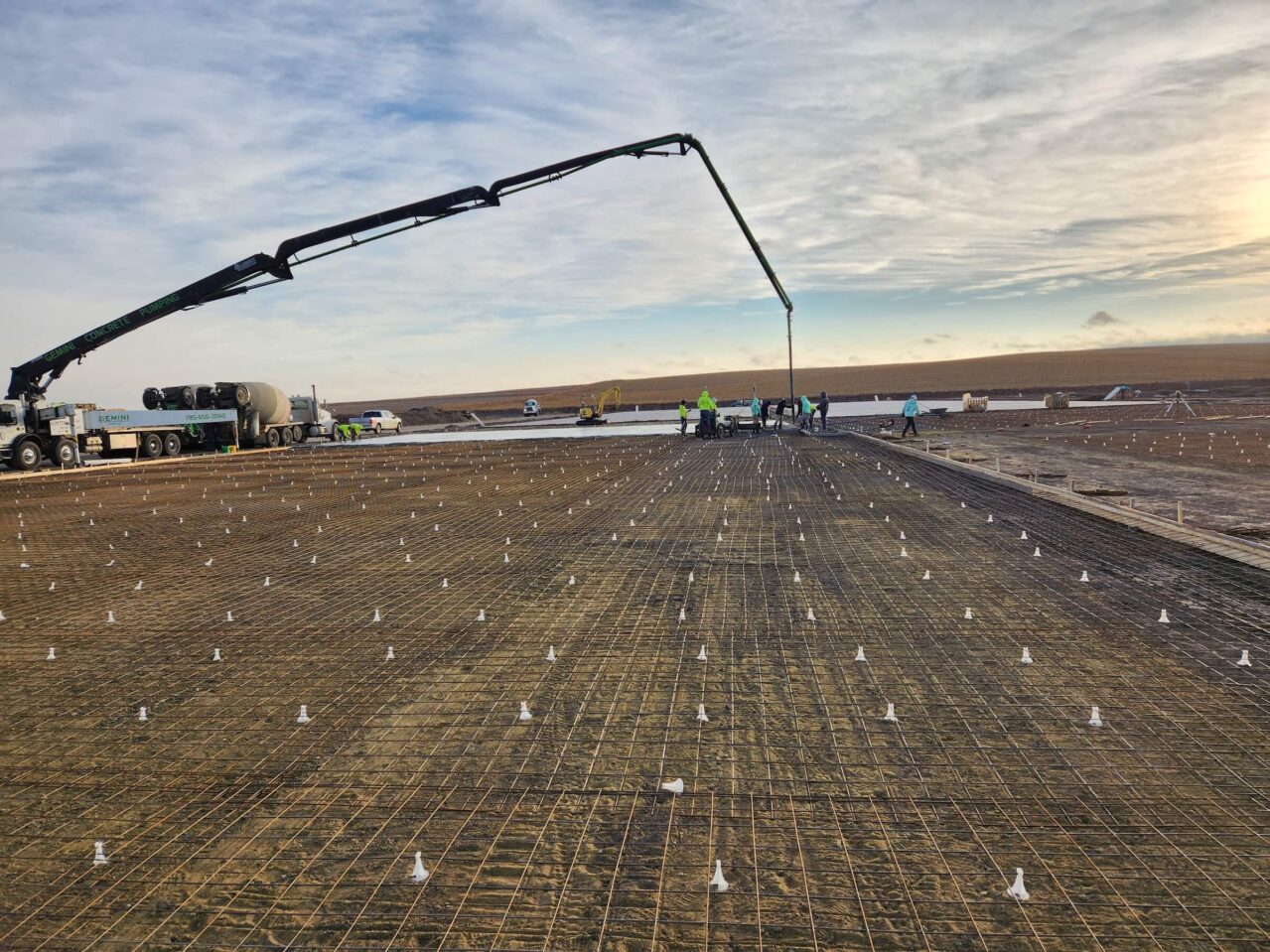

This featured project showcases a modernized sow complex centered on a new all-steel farrowing barn, complemented by two retrofitted barns for gestation and GDU operations. Originally constructed in 2013 by Bower Ag as a 10,000-head wood-frame finishing site, the facility was transformed into a 6,000-sow breeding complex. Following a fire at another location, the customer committed to steel construction for enhanced safety, longevity, and insurability.

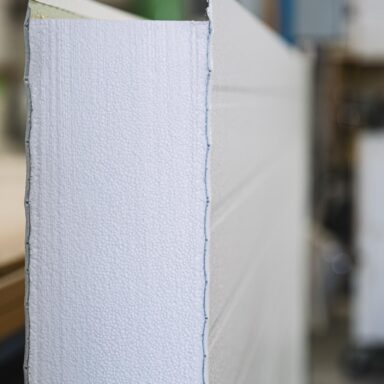

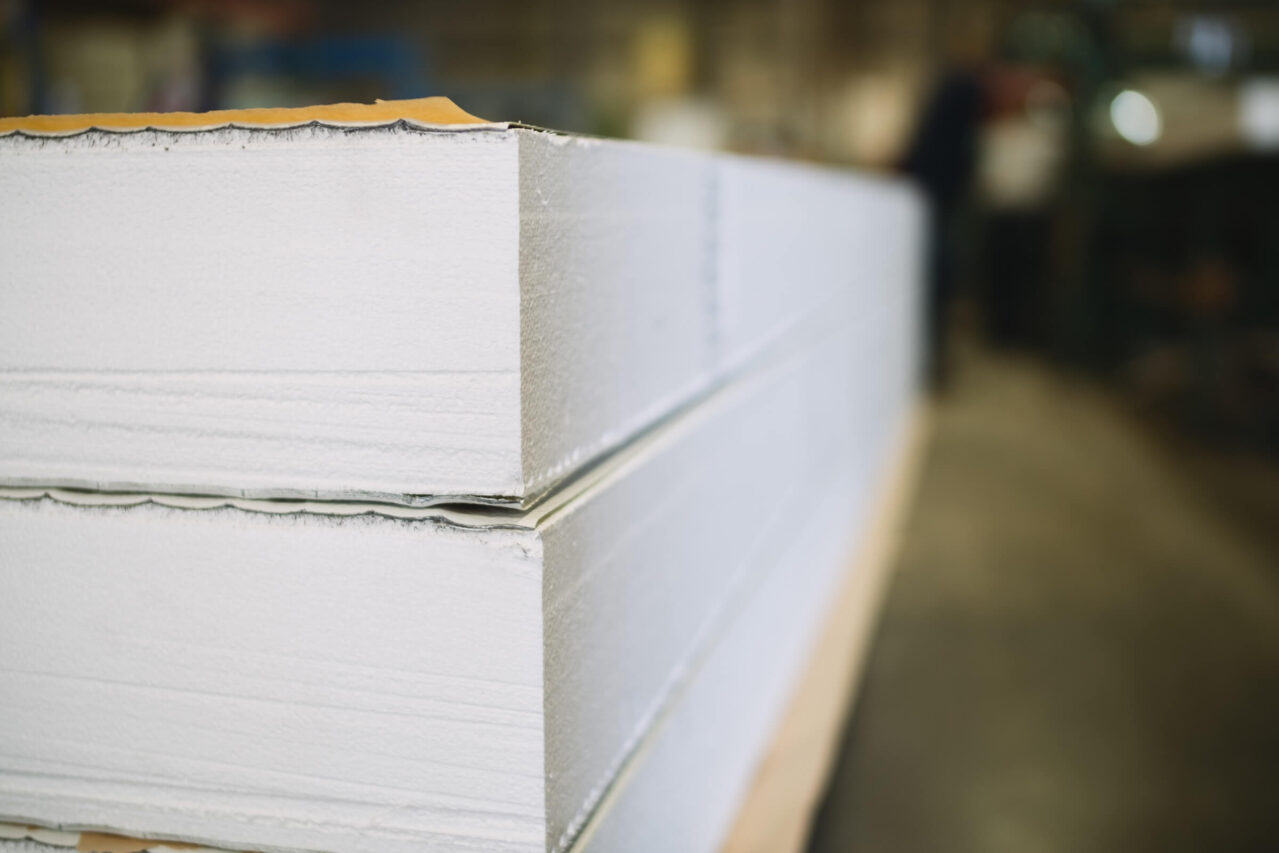

Designed with galvanized steel frames and EPS insulated wall and ceiling panels—the first all-steel sow barn package from EPS—the farrowing barn delivers exceptional thermal performance, air-tight construction, and HEPA filtration, along with a walkable attic that enhances service access and biosecurity. Completed ahead of schedule, the Calvert Sow Complex exemplifies how steel-framed, insulated-panel facilities address fire risk, insurability, and long-term operating costs—providing producers with a reliable, secure, and high-performance solution for modern sow production.

Steel Barn Package

On-Time & On-Budget

Fire-Resistant Design