Key Takeways

-

- Biogas unlocks major revenue for large dairies.

- 3-step systems turn digestate into fertilizer cake and cleaner water.

- Most dairies recoup costs in 3–7 years.

- Digestate is harder to handle than raw manure.

- Centrisys centrifuges remove more solids and reduce lagoon issues.

After covering the fundamentals of dairy manure management—solid separation, sand handling, and on-farm best practices—we’re turning to the next opportunity: converting waste into real value.

Biogas Revenue, Digestate Management, and Fiber Separation

Dairies with over 3,000 cows have significant revenue opportunities in the dairy manure digester and biogas market by owning digesters or selling manure to digester groups. A large dairy digester can generate up to $2.8 million annually from energy and carbon credits alone. However, digestate (material remaining after organic materials are broken down) from anaerobic digestion is more challenging to manage than raw manure—it remains suspended, fills lagoons more quickly, and has a greasy texture that complicates pumping and irrigation.

Proven Three-Step System

Efficient dairy digestate and manure separation relies on a proven three-step system that maximizes nutrient recovery and reduces lagoon loading.

Efficient digestate management uses a three-step process:

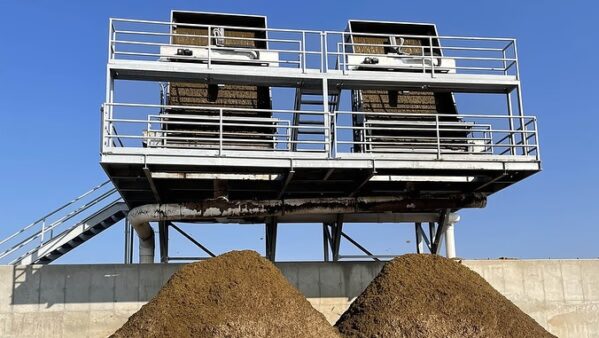

- Primary Separation: Slope screens or dewatering equipment remove large fibers after digestion.

- Secondary Separation: Screw or roller presses dry solids for stacking as bedding or land application, reducing bacterial risk.

- Final Clarification: Advanced centrifuges further reduce solids, clarify water for irrigation, and maximize nutrient recovery.

The resulting “cake” (dewatered solid material) contains up to 25% dry matter, phosphorus, and nitrogen—ideal for fertilizer. Systems must be customized to match local conditions, herd size, and specific goals.

The Science Behind the Spin (3000 RPM/3000 G-Force)

Dairy Specialists and Centrisys pioneered the first decanter centrifuge engineered for dairy manure management back in 2007, and our partnership remains strong today. Over 18 years of innovation, field trials, and joint discussions have produced the DT Model Decanter Centrifuge—made in the U.S.A. for the toughest dairy solids.

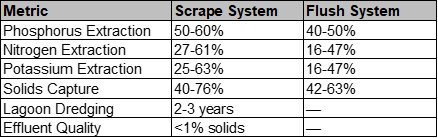

- Dairy-Specific Design: Centrisys separates up to three times the solids of traditional methods, without added chemicals or polymers, and delivers phosphorus reduction of 50–60%.

- Cleaner Results: The system yields centrate with less than 1% solids, which dramatically reduces lagoon dredging, cuts irrigation maintenance, and improves downstream efficiency.

Key Metrics:

Note: For digester-equipped dairies, Centrisys handles digestate without polymers, lowers TSS on fields, and simplifies compliance.

Real-World Results

Oregon: Compliance Without Compromise

A family dairy, without a digester, set out to achieve practical, grant-supported compliance and operational savings. Their vision: a bottom-pit removal system with slope screens to divert solids for on-site composting and route liquids for farm irrigation, cutting hauling costs and runoff. This approach is underway, paving the way for streamlined future compliance.

Nevada: Maximum Efficiency

A large-scale producer’s comprehensive vision includes double-stage separation and a Centrisys centrifuge, aiming for industry-leading clarification and final liquid solids below 1%. As construction and commissioning continue, this system is positioned to set a new standard for clean manure management, enabling herd growth and easier regulatory approval.

Both projects are ongoing, and their progress represents the future of practical, sustainable manure management.

Sustainable Doesn’t Mean Simple or Low Cost

Investing in separators, centrifuges, and digesters ranges from $500,000 for basic dairy manure separation systems to $3 million or more for full systems. Payback often occurs in 3–7 years, driven by savings from energy credits, reduced hauling costs, and improved nutrient management. Sustainability is now essential for protecting productivity, reputation, and legacy.

Your Partner in Progress

We’ll work with you to design and implement a manure solution tailored to your herd, region, and regulatory needs. There’s no one-size-fits-all.

For a refresher on on-farm dairy manure management basics—solid separation, sand handling, and barn-level systems—see Part 1 of this series.

Contact us to explore your options and discover what your manure can do.