Future-ready upgrades for modern operations.

With dairy margins tighter than ever, upgrading your barn isn’t just an improvement—it’s a necessity. Producers who invest in precision technology have reported up to 50% reductions in labor costs and a 10–20% boost in milk yields, directly improving profitability and workflow. Moving from manual routines to automated systems enables early health interventions, streamlines labor, and turns daily data into actionable results.

Teat Dip Sprayer

Sensor

Parlor Automation Upgrades

Upgrade your parlor without starting over. Our automation retrofits transform existing parlors with robotic teat prep, sensor-based monitoring, and intelligent controls that tighten routines while significantly reducing labor.

High-performance tools—including advanced milk meters, flow-responsive milking, sprayers, and custom automation—ensure every stall runs with total consistency. These upgrades unlock more turns per hour, cleaner milk, and better cow care, building a platform that grows with your herd and future technology needs.

Cow Monitoring Systems

Gain visibility with advanced monitoring solutions. Whether using collars, tags, or sensors, these systems keep a constant pulse on every animal in the herd. By tracking health, fertility and rumination, these tools uncover critical data long before changes are visible in the pen.

By flagging cows in heat or at risk of health issues, these technologies support early intervention and tighter reproduction programs. This level of individual visibility allows your team to prioritize labor, target treatments, and protect performance with precision.

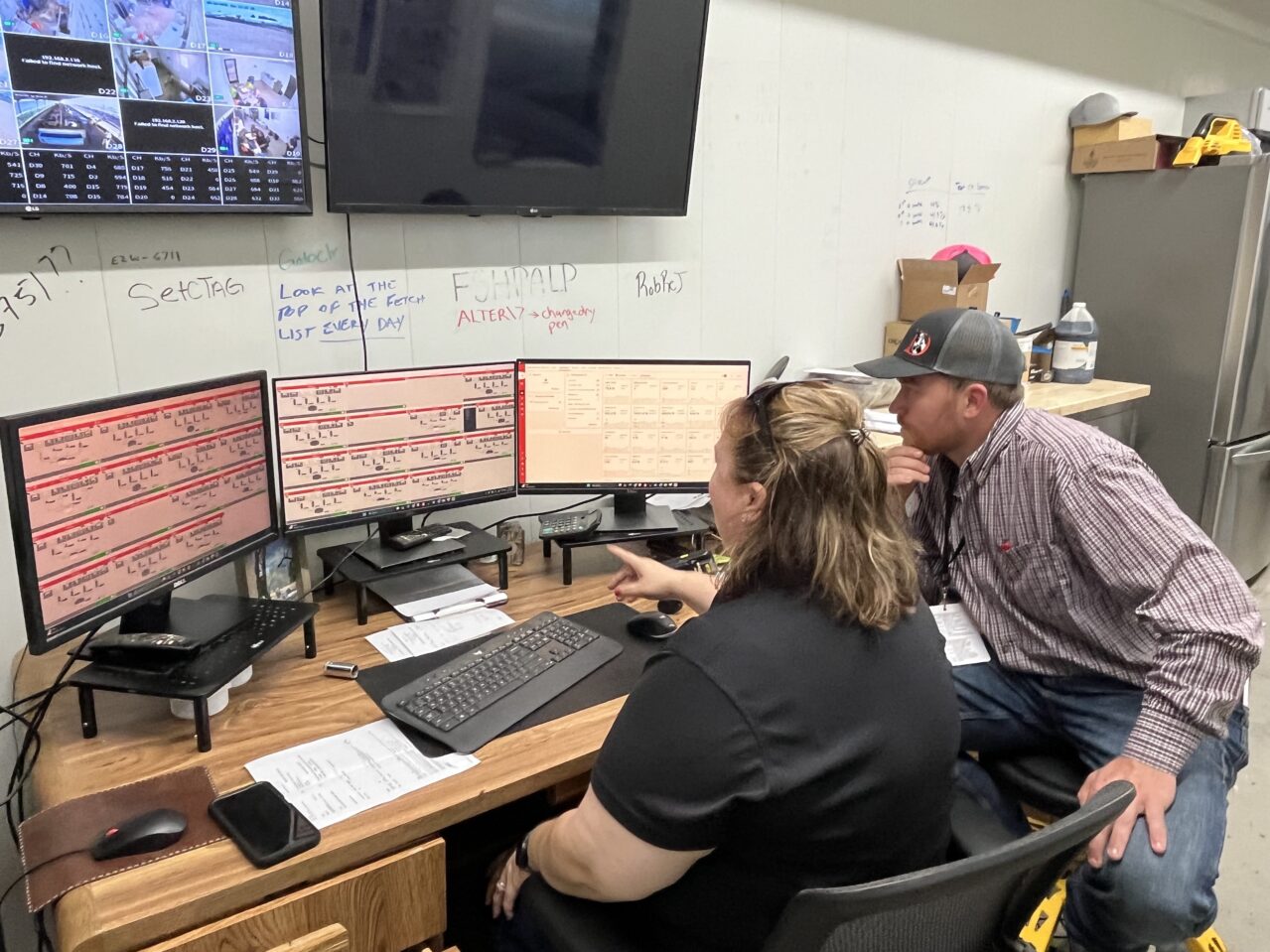

Herd & Data Management

Centralize your operation with integrated data solutions. Herd management software consolidates key information into a single interface, enabling faster, clearer decision-making. These systems unify records for reproduction, health, milk, and labor while integrating data from multiple equipment platforms.

Underneath, automation controllers and cloud databases collect and visualize barn data in real time. This turns equipment metrics into practical insights and performance benchmarks, providing a clear view of your operation.

Barn Automation

Barn automation adds specialized tools to keep cows moving, fed, and comfortable while reducing labor pressure. Solutions like feed pushers, brushes, walk-overs, and automated gates handle the routine chores that otherwise drain time and labor.

By streamlining daily interactions and movement, these additions improve consistency and reduce bottlenecks throughout the farm. The impact compounds as cow behavior and schedules become tighter, resulting in an operation that runs more smoothly with fewer manual tasks.

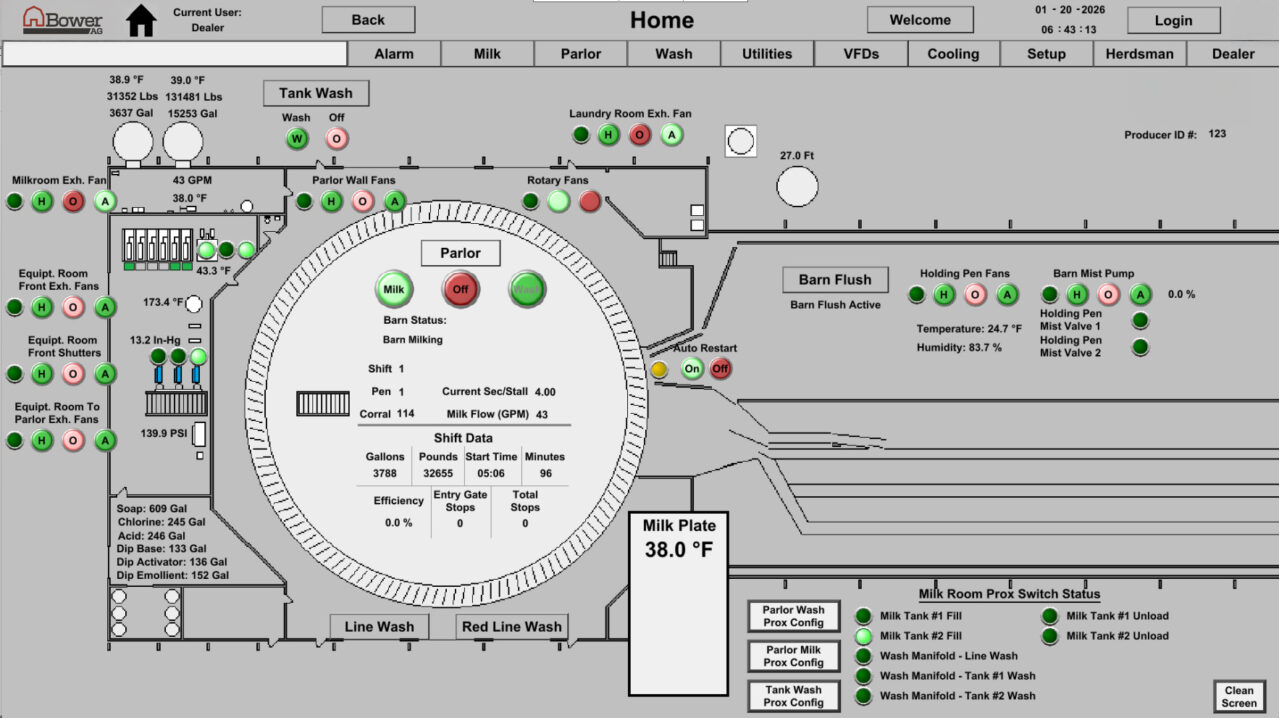

Bower Ag PLC Solution

Bower Ag’s custom-engineered Programmable Logic Controller (PLC) gives dairy operators simple, direct control of every system. Its intuitive interface makes adjustments and diagnostics fast and frustration-free, delivering smoother performance and more reliable automation than generic platforms.

Built specifically for dairy workflows, this specialized hardware keeps your milking operation running efficiently day after day. By unifying disparate components into one cohesive control center, our PLC solution simplifies troubleshooting, protects your equipment from downtime, and ensures your facility operates at peak capacity.