The Bettencourt Dairy #2 Rotary project showcases a highly coordinated dairy equipment installation centered around a 106-stall DeLaval E500 rotary. Building on three prior rotary projects with this customer, our team worked closely with trade partners to deliver a fully integrated milking system—aligning every component, utility connection, and control interface for reliable startup and long-term performance.

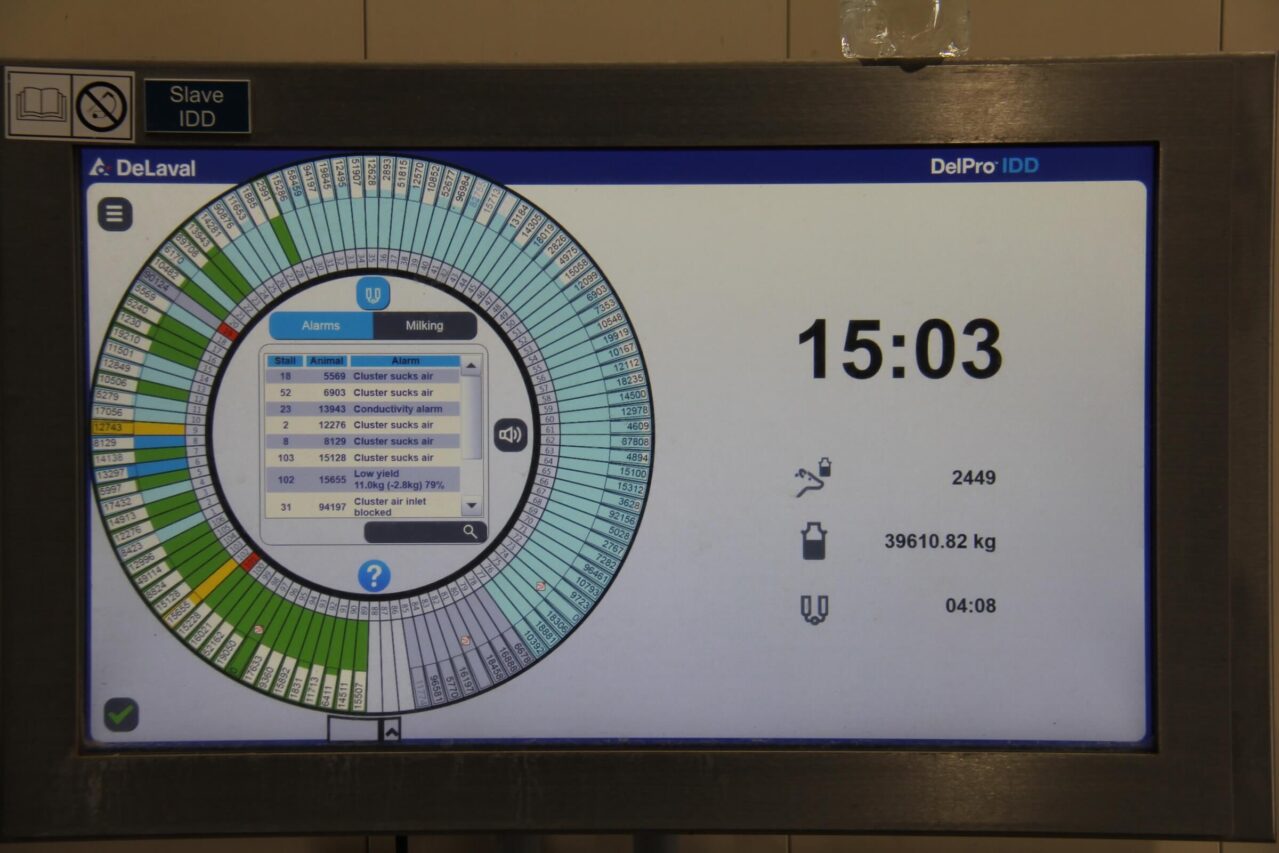

The scope included complete rotary equipment installation, automation and safety systems, RC5 controls, PLCs, VFDs, and full DelPro integration. Beyond the rotary, the project included installation and integration of milkhouse equipment, stainless steel milk and CIP piping, vacuum and compressed air systems, sort gates, crowd gate, TSR robots, chemical delivery systems, and cow identification hardware.

All systems were programmed, tested, and verified to function together as a single, connected milking operation. The result is a high-capacity rotary parlor where cow flow, milk capture, and system automation are synchronized, helping Bettencourt Dairy #2 capture the full performance potential of the E500 rotary investment.