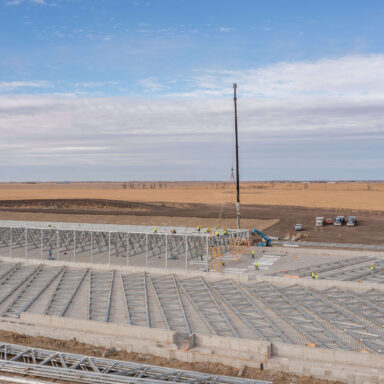

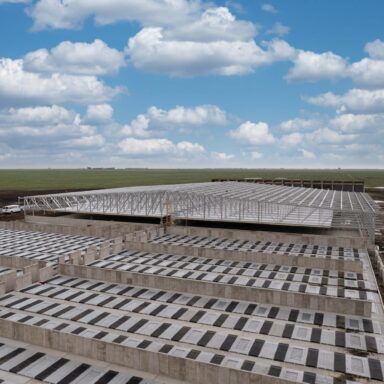

This featured project showcases a next-generation 12,000-head sow complex, the first prefabricated all-steel swine barn built in the United States. The steel design replaces traditional wood with galvanized steel frames and PIR insulated metal panels to create a more biosecure, flame-retardant, energy-efficient, and durable environment for high-density sow production. And a walk-able attic.

The steel structures deliver faster, cleaner construction, strong clear-span interiors, and smooth, easy-to-wash surfaces that support hygiene and uninterrupted ventilation, while meeting demanding R-value targets for filtration and pig comfort. Paired with advanced feeding, bin scale, ventilation, and EDGE 2 control technology, this complex is engineered to handle more than 45 million pounds of pork per year and is positioned as a model for the future of large-scale, risk-aware sow production.

First All-Steel Sow Complex

12,000-Head Sow Site

Steel + PIR Sandwich Panels